Forgeweld Consumables

Forgeweld Consumables

Forgeweld Ltd have for many years specialized in the welding support products market.

Supplying consumables and equipment for the Maintenance, Forging, Tool & Die, Agriculture, Dairy, Aerospace, Quarrying, Pharmaceutical, and Refrigeration industries to name just a few.

With many years experience in this field, we believe that our ability to communicate and advise on a professional and friendly level is second to none.

We have a wide range of specialist welding and brazing consumable products to suit all needs. These include Inconel, Cobalt, Nickel Alloys, Stainless, Titanium, Silver, Copper, Cast Iron, Hardfacing, High Tensile and Mild Steel.

These are available in MMA Electrodes, MIG, TIG and Sub Arc Wires, brazing and silver solder rod, powders and fluxes.

Manual Metal Arc (MMA)

A range of MMA electrodes designed for ease of use in the forging industry.

Products ranging from Gouging Electrodes for weld preparation of dies and crack removals to Iron Nickel and Cobolt materials.

Forgeweld E510

Manual Metal Arc (MMA)

High recovery cobolt based electrode designed for the forging industry to combat all four elements of wear, i.e., heat, impact, corrosion, abrasion. Especially where higher impacts are required at temperature.

Excellent for rebuilding corners with minimum base dilution. Has the ability to overlay extensive areas without cracking. One of the most widely used cobolt-based electrodes for high temperature wear resistant applications, i.e., hot shear blades, punches and dies, ingot tong ends, and hot steel handling equipment.

High resistance to cracking, wear, heat, impact and corrosion resistant.

Forgeweld E530

Manual Metal Arc (MMA)

Superior specially designed high strength colbolt-iron-chromium type electrode for the tool and die industry. FWE530 is designed to combat all four elements of wear, i.e, heat, impact, corrosion, and abrasion.

Overlaying of extensive areas can be achieved without cracking. Excellent for rebuilding form edges and corners with minimum base metal dilution. Will retain hardness at elevated temperatures, the welds are machineable and will work harden under impact.

High resistance to cracking, wear, heat, impact and corrosion, makes this an excellent product for use on shear blades, clipping tools and forging punches.

Forgeweld E531

Manual Metal Arc (MMA)

Cobolt based electrode designed for the forging industry to combat all four elements of wear, i.e., heat, impact, corrosion, abrasion. Especially where higher impacts are required at temperature.

Excellent for rebuilding corners with minimum base dilution. Has the ability to overlay extensive areas without cracking. One of the most widely used cobolt-based electrodes for high temperature wear resistant applications, i.e., hot shear blades, Hot Trimming dies, ingot tong ends, and hot steel handling equipment.

High resistance to cracking, wear, heat, impact and corrosion resistant.

Forgeweld E540

Manual Metal Arc (MMA)

Superior specially designed high strength, low hydrogen electrode for heavy plant repairs and the reclamation of large die blocks. The welds are machinable, FWE540 can be used in practically every area of the forging industry.

High resistance to cracking, wear, and impact.

Pre-heating prior to welding is essential, and PWHT is invariably applied.

Forgeweld E590

Manual Metal Arc (MMA)

An electrode specially designed for cutting, gouging and piercing operations on all metals without the use of air or oxygen. The force of the arc sears the metal surfaces leaving them clean prior to subsequent welding operations. Applications include any ferrous or non-ferrous materials typically, armour plate, cast iron, stainless steel and hardenable steels.

Easy to use with little skill required. Operates at lower current and produces less fume than would normally be expected from an electrode of this type. Smooth and even grooves are easily produced.

The electrodes are ideal for back gouging of butt welded seams and almost indispensable for the preparation of cast iron.

Forgeweld AP Smooth

Manual Metal Arc (MMA)

Superior all positional electrode for the repair and fabrication of low carbon steels.

Smooth forceful arc, low spatter, easy slag detachability.

Suitable for all mild steel fabrications and repairs.

Particularly suitable where welding has to be carried out in awkward positional places.

Forgeweld LoHi

Manual Metal Arc (MMA)

High quality superior all positional low hydrogen electrode containing iron powder to provide 120% metal recovery.

Easy strike, easy to use, smooth flowing electrode with low spatter and self releasing slag. Welds are of a smooth appearance, ductile and of good radiographic quality.

For welding mild and medium tensile steels and for BS4360: 1972 steels where low hydrogen levels and crack resistant welds are required. Particularly suitable for welding heavy sections.

Forgeweld NiFi

Manual Metal Arc (MMA)

The electrode is designed to deposit a high strength machineable weld for the joining and building up of cast irons.

Low amperage, smooth arc, minimum spatter and high resistance to cracking. For the repair of grey, SG, nodular or ductile irons where higher strength is required, free from cracks and porosity.

This electrode is also designed for joining cast iron to mild steel. Use with Forgeweld E590 gouging for preparation work.

Forgeweld HF34

Manual Metal Arc (MMA)

The electrode is designed to deposit wear resistant overlays on all ferrous metals where high resistance to impact and abrasion is required.

The electrode is all positional with a metal recovery rate of 110%. The welds are non-machinable in the as welded state but can be softened by heat treatment at 720 - 750 deg C.

After machining the welds can be rehardened by oil or water quenching.

Applications include earth moving equipment, scrapper blades, bucket lips and facings, farm implements and any applications subject to impact and abrasions.

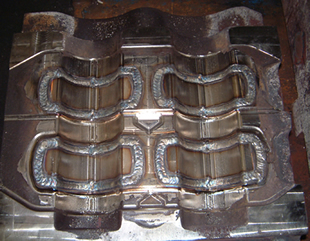

Metal Inert Gas (MIG)

Wires designed and extensively used for repairs to complete Flood Welding of blocks from 10kg to 10 tonnes in weight.

Flux Cored, Metal Cored and Solid Wires to suit all requirements.

Forgeweld FW4

Metal Inert Gas (MIG)

A highly effective flux cored wire for die repairs requiring hardness 38-45Rc

A high strength tubular continuos wire where high deposition with a good stable arc is required for the general repair and maintenance of forging industry dies and blocks.

Tough resistance against impact,compression and abrasion.

PACKAGING 1.2 mm & 1.6mm 15kg rls.

Forgeweld FW4 D 37-G

Metal Inert Gas (MIG)

Special tool steel Iron base alloy designed to refurbish dies in the automobile industry.

Suitable for: Punching tools, forming tools, dies.

Typical Chemical Analysis

-

- C

- Mn

- Si

- Cr

- Ni

- Mo

- Fe

-

- All Weld

- 0.20

- 0.6

- 0.2

- 9.1

- 1.5

- 2.4

- Bal.

Typical Mechanical Properties

Hardness as welded: 45 HRc.

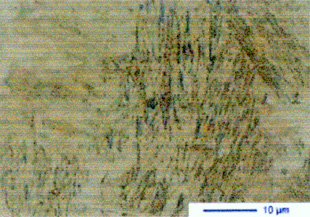

General Characteristics

- Microstructure

- Machineability

- Oxt-acetylene cutting

- Deposit thickness

- Shielding gas: Argon 98% + Oxygen 2% or Argin 82% + CO2 18%

Welding Parameters & Economical Data

-

- Diameter (mm)

- Current (A)

- Voltage (V)

- Stock-Out (mm)

- Gas Rate (l/min)

- Article Code

- Packaging

-

- 1.2

- 200-300

- 25-31

- 20 max

- 12-15

- N/A

- Spool 15kg

-

- 1.6

- 250-450

- 25-31

- 20 max

- 15-18

- N/A

- Spool 15kg

Forgeweld FCW510

Metal Inert Gas (MIG)

High recovery cobolt based flux cored wire designed for the forging industry to combat all four elements of wear, i.e., heat, impact, corrosion, abrasion. Especially where higher impacts are required at temperature.

Excellent for rebuilding corners with minimum base dilution. Has the ability to overlay extensive areas without cracking.

One of the most widely used cobolt-based wires for high temperature wear resistant applications, i.e., hot shear blades, punches and dies, ingot tong ends, and hot steel handling equipment.

High resistance to cracking, wear, heat, impact and corrosion resistant.

Forgeweld FCW531

Metal Inert Gas (MIG)

Cobolt based flux cored wire designed for the forging industry to combat all four elements of wear, i.e., heat, impact, corrosion, abrasion. Especially where higher impacts are required at temperature.

Excellent for rebuilding corners with minimum base dilution. Has the ability to overlay extensive areas without cracking. One of the most widely used cobolt-based wires for high temperature wear resistant applications, i.e., hot shear blades, Hot Trimming dies, ingot tong ends, and hot steel handling equipment.

High resistance to cracking, wear, heat, impact and corrosion resistant.

Forgeweld MAG550

Metal Inert Gas (MIG)

Superior specially designed high strength austenitic type wire of duplex structure for overlaying all steels. The percentage of ferrite in the austenitic matrix gives a high resistance to weld metal cracking.

Overlaying and joining dissimilar steels to one another, high and low carbon steels, spring steels, tool and die steels, cast steels, ferritic to austenitic steels and steels of unknown composition. One of the most universally used wires for problem and unknown steels. Has uses in practically every type of industry.

High resistance to cracking, wear, heat, impact and corrosion resistant.

Forgeweld MAG52

Metal Inert Gas (MIG)

Superior wire for overlaying a whole range of tool and die applications where general hard surfacing is required to give > 50HRc.

FW52 has primarily been developed along the lines of the popular H13 Type wires for the repair and rebuilding of hot working tool and dies.

FW52 structure has been slightly developed to give a smoother deposit and a slightly better wear performance than a normal H13.

The alloy deposit ensures air hardening characteristics coupled with excellent toughness and abrasion resistance at particularly high temperatures.

Tungsten Inert Gas (TIG)

A comprehensive array of TIG wires for intricate repairs, Flash Line Reclaims, Clip Tools, Punches, Small GFM Tools and Machine Shop Repairs to name but a few.

Forgeweld 52TIG

Tungsten Inert Gas (MIG)

Superior wire for overlaying a whole range of tool and die applications where general hard surfacing is required to give > 50HRc.

FW52 has primarily been developed along the lines of the popular H13 Type wires for the repair and rebuilding of hot working tool and dies.

FW52 structure has been slightly developed to give a smoother deposit and a slightly better wear performance than a normal H13.

The alloy deposit ensures air hardening characteristics coupled with excellent toughness and abrasion resistance at particularly high temperatures.

Forgeweld 550TIG

Tungsten Inert Gas (MIG)

Superior specially designed high strength austenitic type wire of duplex structure for overlaying all steels.

The percentage of ferrite in the austenitic matrix gives a high resistance to weld metal cracking.

Overlaying and joining dissimilar steels to one another, high and low carbon steels, spring steels, tool and die steels, cast steels, ferritic to austenitic steels and steels of unknown composition.

One of the most universally used wires for problem and unknown steels. Has uses in practically every type of industry. High resistance to cracking, wear, heat, impact and corrosion resistant.

Forgeweld GAS510

Tungsten Inert Gas (MIG)

As with the cobolt based electrode, designed for the forging industry to combat all four elements of wear, i.e., heat, impact, corrosion, abrasion. Especially where higher impacts are required at temperature. Dilution is easily controlled with the gas method.

Excellent for rebuilding corners with minimum base dilution. Has the ability to overlay extensive areas without cracking. One of the most widely used cobolt-based products for high temperature wear resistant applications, i.e., hot shear blades, punches and dies, ingot tong ends, and hot steel handling equipment.

High resistance to cracking, wear, heat, impact and corrosion resistant.